I’ve been doing some reading on the California Portabote Group, and it appears that my unnerving experiences with the “Flexi-Splay” effect has been documented by other owners for quite some years. Even though they used different expressions like “bowing out” and “side flaring”, their experiences pretty much matched mirrored mine.

Excerpts:

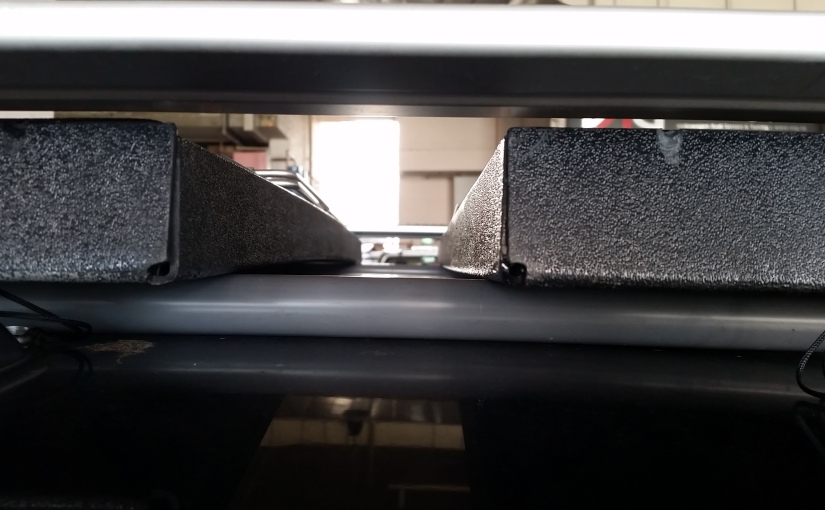

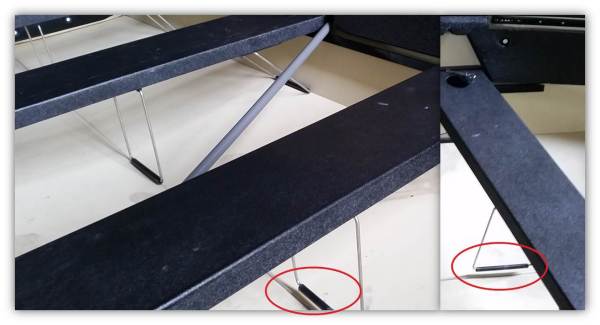

I noticed that at one point, when the boat was planing and getting up to maximum speed, the edges bowed out as if the boat was going to collapse from the centre. One gunwale was almost under the water. It looked as if the only thing stopping it folding up was the pin in the middle seat. The seat itself was almost out of the bracket. When I grabbed both sides of the boat and pulled in, the speed of the boat increased by 2 to 3 kilometre per hour. When I moved to the back seat the sides returned to their normal upright position.

I took it out this morning and watched the gunwales as I throttled up. At around 10 MPH the gunwale over the center seat begins to move outward. AT 13 mph it has moved about 5 inches. I had never noticed it before. On mine the starboard side is more pronounced, probably because there is more weight on that side.

I have had some concerns when I’m in rough water by myself sitting in the back seat. That would make 300+ lbs. (motor, gear and myself) in the rear third of the boat. I still have draft but it is close. I recently made an extension for the tiller so I can move my driving seat to the middle. This is the best position because I can access the entire boat comfortably. The problem is now when I’m at full throttle the right side is pulled toward the water. I try moving my weight around and it doesn’t seem to make a difference. Has anyone else experienced this?

Then, we put the 9.9 hp Mercury on it; with our same load, the boat quickly accelerated to over 17 mph, but was starting to deform above that speed, with the left gunnel bending way out. The boat still seemed to handle ok, and was undoubtedly still safe, but my bride was uneasy watching the deformation, so we didn’t try to go faster.

…my max useable speed was about 13mph. After this the bottom sucked down under the middle seat, the sides started to bow out and spray came over the sides. Yes I could get 18mph with one up but the boat was in my opinion unstable at any speed over 13mph.

…the left side flexes out at max speed. The right one stays upright. Even when the boat isn’t moving at all, the left side bows out in the middle by a couple of inches. The right one does not. Not planning to add a bigger motor, I have a 6hp and it’s plenty for me.

I was waiting for delivery of my new 14ft PB and had not yet sold my 12ft PB. I traded in my 6hp 4 stroke for a new 9.9 two stroke Tohatsu so had to try it out on the 12. I got to tell yea, NEVER TRY THIS!!

There were no problems as long as I had a couple people in the boat and only ran the motor at half throttle, beyond that the sides of the hull would start to deform drastically.

After I dumped everyone off on the beach I decided to take the boat out by myself and see what it would do without the extra weight. I slowly increased throttle toward WOT but never made it, the bow all on a sudden began to fold back on itself. As soon as I saw this happing I cut the power, but it was just shy of having the bow in my lap; the hull was never the same.

I’m going into my 3rd year with my 14 footer and only have one complaint, the port side bows out around the location of the forward ore locks at high speed. I can minimize this problem by running a line between the forward ore locks, thus preventing the sides from bowing out; This is not a problem when there is only one person and a little gear in the boat, but when you add another adult or two the situation manifests itself, and only at high speeds. I’m running a 9.8hp 2-stroke so I’m within the boat power limits. Other owners have voiced similar concerns so I don’t think I’m alone here.

The above posts documented basic information about the incidents, but (generally) did not include information on hull length, hull series, on board load balancing, outboard size, speed, throttle level, and surface conditions. (The assumption here is that every little factor adds to the equation.) There were also other owners on that same group who hinted at the issue or made passing references, but who never documented the specifics of their personal experiences. I skipped those to focus solely on the reported incidents.

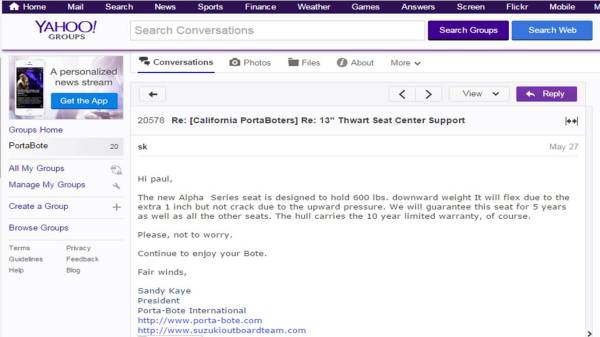

In response to some of the above posts, the manufacturer reminded the group of instructions in the owners handbook (post 3726).

6. “FLEXING”: When you step on the “floor of your boat, you will notice a certain amount of flexing in the “floor’. This is normal. Also, when the hull begins to “plane”, the sides will flex out and the floor bottom will flex “down”. This, too, is normal. This “flexing action” actually absorbs and cushions much of the impact of strong waves that might capsize an ordinary rigid hulled craft. The transom will flex, also. However, if one or both of the sides of the hull begin to flex or deform “abnormally”, you are traveling beyond the “MAXIMUM SPEED CAPABILITY” of the hull. Immediately reduce engine rpm. This flexing will stop and you will find you are traveling at almost the same speed, comfortably. (NOTE: No matter how large an outboard you install, your Porta-Bote hull cannot go any faster than its “MAXIMUM HULL SPEED”. It will just start to flex abnormally.) Never try to make a sudden “sharp turn” when traveling at high speeds in this or any boat.

Which is fair, logical advise. Folded hulls can never have as much rigidity as solid hulls, and this hull wasn’t made for outright pace.

Having said that, there will be situations where slowing down is not a logical option, either because of obvious danger (in the form of the Weserwolf), or because speed is already way low.

Did you see the size of that bow wave? 😀

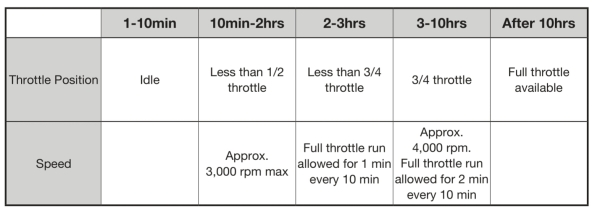

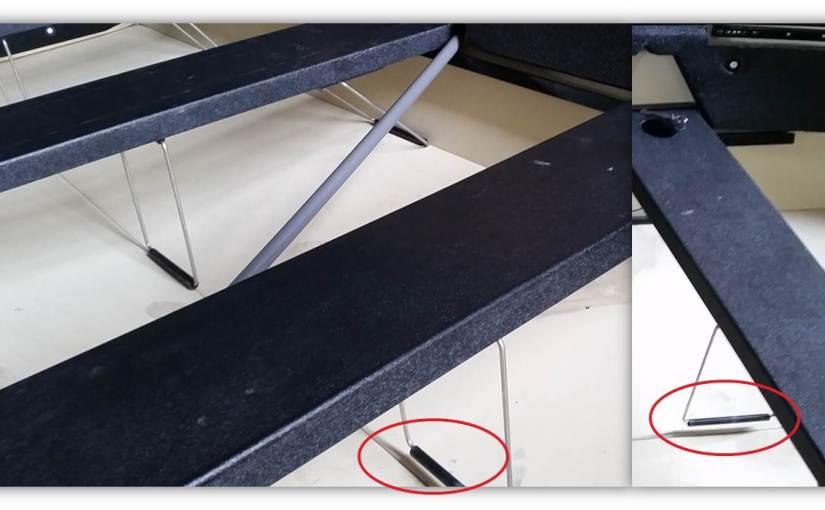

In both my incidents, load management as well as prevailing sea conditions were the key triggers rather than speed or throttle position. We had launched on back-to-back days to clock up the required 10 hours run in for the Tohatsu outboard, and throttle position had to stay between idle and 75%. In no way could speed, torque, or sudden acceleration have been an issue.

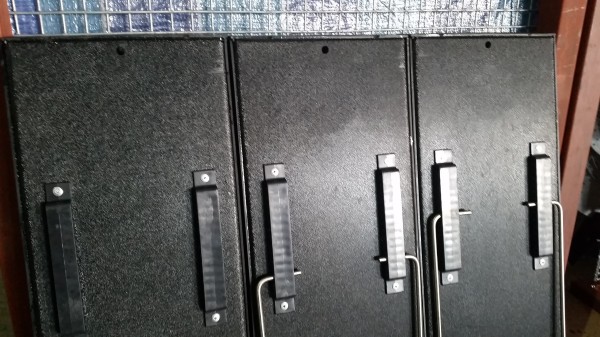

Here’s the run in schedule for the Tohatsu M9.8B. My first incident happened in the third hour, while the second incident happened in the eighth hour.

There will be days where one needs to boot the craft to get out of danger, or perhaps to get back to shore in a hurry. On those very days, I wouldn’t want the hull to splay and slow me down, or (worse) bow out and start taking on water.

The search for a fix continues.

Fair winds

1.373869

103.835738